The Future is Modular

Cpac Modular are proving to be a faster, greener and smarter way to build.

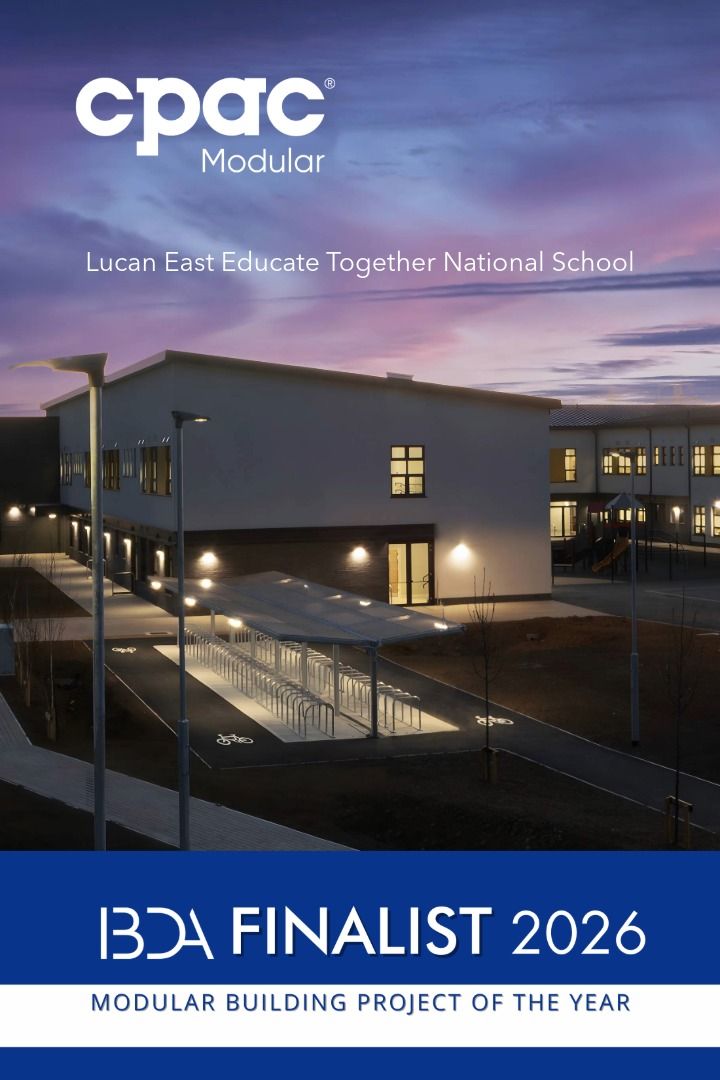

With increased focus on turnaround and sustainability for mid to large scale construction projects, many are now looking towards modular and hybrid modular methods as effective solutions. Cpac Modular, with over 30 years heritage in modular construction development, have recently re-branded and re-focused their efforts to several new and innovative products and longer lasting modular construction techniques. Cpac Modular boast that they can assemble 90 units into a three story building in just three days.

“Modular is more cost-effective and can be up to 50% faster to complete than traditional builds.” says Alan Boyce, Marketing and Bid Manager with Cpac Modular.

“From a concept sketch or an architects proposal Cpac Modular can develop a full end to end, design and construction programme. We have the one of the most expert teams in the UK or Ireland and they can guide you through the process that can bring even the most ambitious ideas to life.”

Cpac Modular, have indeed been working on a wide range of innovative and challenging projects over the past number of years and in particular during 2020 when apart from major projects to tackle C19 with a number of Test Centres, increased hospital projects and a major facility at St. Vincents University Hospital, as well as their own Safegate Hygiene Pod, they also completed Ireland’s largest welfare and catering facilities for one of the country’s biggest tech employers.

This multi story building not only facilitates employees in terms of welfare and shower rooms, but also houses Ireland’s largest restaurant which feeds up to 4,000 employees daily. In addition, the company boasts that it has built enough educational space for over 4,000 school children and enough healthcare projects to accommodate over 1,150 bed spaces in the last 2 years alone.

Cpac Modular act as an agent for planning and building regulation approvals where required and in general will manage a project from building design through site investigations, services design, planning permissions, building regulations and also recommend any additional sustainable features to the design.

Their construction division manage the entire build programme and a dedicated contracts manager oversees the construction phases from the foundations and services to the factory build and installation of the building. To complete the site Cpac Modular can also take care of parking facilities, landscaping and internal fitout too.

While the site and foundations are being prepared, the Cpac building is already being manufactured in their large facility in Dunshaughlin, County Meath where they employ over 70 specialist workers as well as a full design team focused on BIM. Factory manufacture means a more dependable build programme that is not subject to weather or site conditions.

Manufactured under controlled factory conditions by skilled workers, to strict tolerances and to a stringent ISO quality control programme means the highest quality of build is achieved. As much of the build program is done in a controlled factory environment, waste is minimized and nearly all materials used are recyclable. So next to nothing goes to landfill.

“With up to 80% less activity on site. Modular constructed buildings cause less disruption and damage to the local environment and to wildlife whilst improving safety and security. In addition, with a faster production time you can occupy your building earlier and start getting a return on your investment sooner.” says Tadhg Twomey, MD of Cpac Modular.

Maintained correctly, Cpac Modular buildings have the potential to last for over 60 years. Cpac Modular buildings can also be relocated making them an even better long-term investment than traditional buildings.

“Short term space provision, especially in the in the Education and Healthcare sectors, has traditionally seen the provision of “Grey Box” style pre-manufactured units. This type of product, although purposely designed to suit a limited lifespan, can often lack relevance and optimal performance if used past the limited lifespan resulting in possible costly maintenance and much higher operational costs particularly in regard to heating and cooling.” Says Alan Boyce.

“We have recently introduced an enhanced product, ‘Cpac Hybrid Modular’ which achieves the look, feel and performance of an architecturally designed, traditionally built, structure but is delivered utilising Modern Methods of Construction and is manufactured off site to the highest quality and building standards delivered in less than 50% of the time taken to build from the ground up”.

The actual time on site can be up to 80% less than traditional build. While the benefits of considerably longer use in optimal performance together with prolonged cost savings on maintenance, heating, and cooling.

Architecturally finished exteriors can be tailored to conform to the local vernacular, a higher specification internal fit out with identifiable architectural features and steel frame structure, as opposed to grey box timber frame. This gives a longer lifespan and their modern heating and cooling systems also achieve NZEB (Near Zero Energy Building) standards.

One recent example of Cpac’s Hybrid Modular work is their project for Griffeen Community College. Here, a new 2 storey building was required to sit beside an existing, traditionally built modern three storey school. Cpac’s Hybrid Modular building was constructed off-site and architecturally designed to the highest specification with the look and feel of a ground up build; “this project stands as a best in class example of what modern school space provision can be” says Martin Murray, Sales Manager, Cpac Modular. “Our method of construction stems from our drive to deliver eco-friendly projects.”

The Griffeen Community School project meets all new requirements brought under the Building Directive (recast) 2020, achieving an NZEB standard. Renewable energy is utilised within this build by the use of air-source heat pumps, thus minimising the carbon footprint of the build over its lifecycle.

The building envelope was designed to complement the existing facilities and the local vernacular. A range of façade materials including an architectural micro-rib steel panel system with associated trims and an architectural fibre cement panel system. The windows include a glass spandrel panel which colour matches that of the existing facilities to ensure continuity of design throughout the entire facility.

Maintaining a comfortable indoor temperature was achieved at design stage through detailed analysis of the building fabric, building orientation, natural ventilation considerations and mechanical heating requirements.

BIM (Building Information Modelling) enables this transparent, collaborative approach. An intelligent 3D computer model is designed and shared with the client and all relevant stakeholders throughout the entire process. BIM allows for even the most non-technical stakeholder to fully engage and interrogate all aspects of the building.

“The 3D modular volumetric construction of this building enables a transparent and collaborative approach to design considerations. We engage with clients at an early stage to ensure all their requirements are achieved during the build. “ says Martin Murray.

If you would like details of Cpac’s Hybrid Modular solution or Safegate Hygiene Pod see cpacmodular.com or contact Alan Boyce (087 778 9193) or Martin Murray (087 390 0274).